Project Support

Spare parts manufacturing projects are carried out to improve production processes and increase the capacity of manufacturing facilities. These projects provide resources to enhance the efficiency of equipment used in production, optimize processes, and develop the technical skills of employees. They also offer training and guidance to maintain quality standards on production lines and ensure that processes run more efficiently. This work is critical for ensuring reliability in production and achieving error-free manufacturing. Thanks to project support, quality and continuity can be ensured in spare parts production.

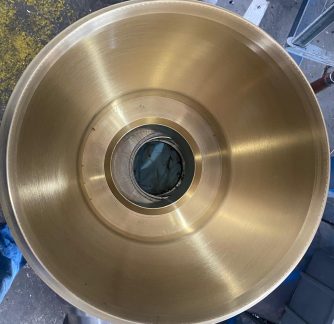

Machine Spare Parts

One of our most important responsibilities is managing the production process of high-quality spare parts by collaborating with different teams. Working with experienced engineers and continuously sharing knowledge is essential for improving production techniques and optimizing processes. It is also part of our responsibility to show new employees the practices on production lines and guide them accordingly. In this way, every part is produced with accurate measurements and quality standards are maintained. Using data-driven control and recording systems throughout production minimizes errors and enables continuous improvement of manufacturing processes.

The key message that emerges throughout all our production processes is that quality and efficiency must always be prioritized.

Using the correct materials and equipment in spare parts manufacturing is one of our core motivations. However, training teams to use these tools efficiently and accurately is equally important. Our ultimate goal is to ensure that every production line and every employee has the necessary resources, knowledge, and support. Proper planning and process management guarantee continuity and quality in production. Through training and operational support, errors are minimized and production efficiency is increased.

Operational and Technical Support

Meetings with our teams reveal that there are many areas in need of improvement. The accuracy of the spare parts used in the production process is closely related to employee experience and effective process management. Therefore, developing evidence-based methods to determine how processes can be optimized is critically important. In addition, documenting all operational and production steps and ensuring transparent management allow processes to be carried out safely and efficiently. Operational and technical support is indispensable for achieving sustainable success in production.

Continuous Improvement

These strategies will become even more important in the coming months. New methods aim to optimize processes by focusing on the needs of production teams. For example, training programs and guidance provided on the production line can increase team efficiency. Moreover, process improvement and quality control practices help minimize production errors. In this way, quality, speed, and reliability are ensured in spare parts manufacturing. All efforts aim to enhance production efficiency and guarantee customer satisfaction. Every part is produced with accurate measurements and standards, production processes run efficiently, and teams are continuously developed.