One of the most rewarding aspects of fixture manufacturing is collaborating with various teams that demonstrate a deep commitment to precision, efficiency, and safety in machining processes. Sometimes these are engineers with many years of experience specializing in CNC fixtures or custom tooling, and I greatly enjoy learning from their expertise on how fixture designs have evolved to meet modern manufacturing challenges. As part of our continuous improvement efforts, I also try to engage with designers or technicians who are new to the production process; working with people who research innovative materials and fixtures but hesitate about practical implementation allows me to explore ways to improve accuracy, error reduction, and training processes for all production personnel.

The most important lesson that emerged from all the production projects we carried out this year was this: High efficiency and precision goals must guide fixture design.

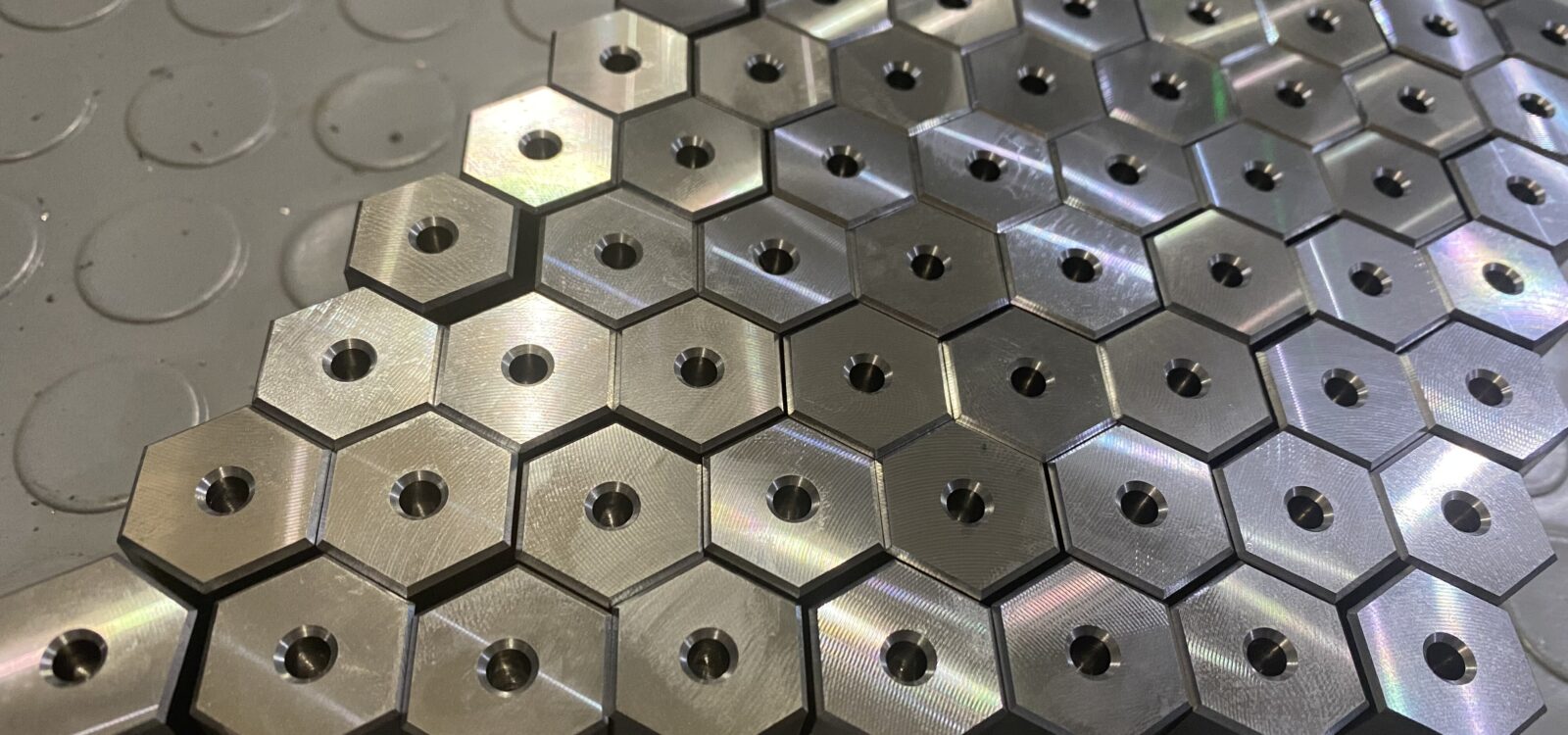

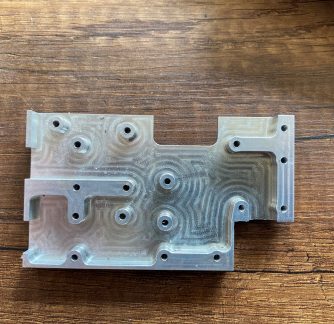

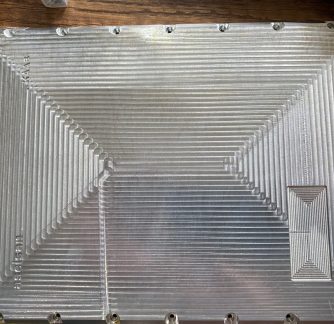

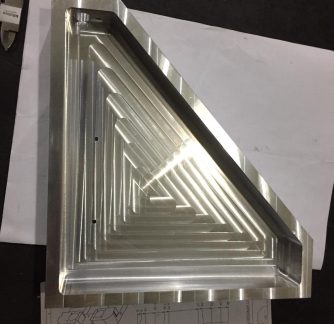

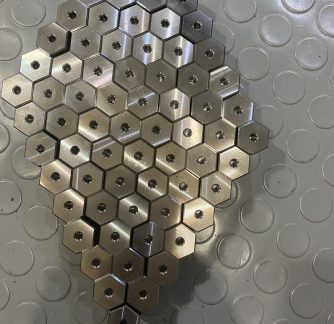

The key insight that emerged from all the projects we undertook this year was that fixture design should be driven by the specific requirements of the parts to be machined, as well as the goals of efficiency and repeatability. Although increasing production speed has always been our primary motivation, we have not always been able to fully prepare our teams to implement fixtures that ensure maximum consistency and reliability. Our ultimate goal is to work together with operators and engineers to ensure that each part—regardless of complexity, size, or material—is produced with the highest precision and reliability. Custom fixtures are a way to prevent setup time, alignment errors, and tool wear from becoming obstacles to productivity, and advanced manufacturing practices provide the operational and technical support required for modern industry. Only in this way can teams achieve optimal performance and consistently maintain high quality standards.

Operational and Technical Support

Meetings we have conducted with engineers and technicians in the field reveal that we still have not reached the level of excellence we aim for. Although we have developed custom fixture designs and manufacturing methods, simply having production equipment is not enough. Effective and consistent fixture usage requires correct investment in both teams and tools. Indeed, it is not sufficient to merely communicate a process culture; we must develop evidence-based methods and demonstrate how and under what conditions fixtures are applied in order to enhance productivity and quality in production. Furthermore, we must be transparent about how we carry out these activities—for example, we should document production processes and share data related to team workflows.

Data-Driven Manufacturing

- Although we have reached some early conclusions regarding the challenges in our field, our primary mission is to determine the most effective methods for fixture design and manufacturing.

- During our discussions with the production team, the most frequently mentioned topics were the following:

- How can we more effectively communicate fixture design and implementation to our teams in a way that increases efficiency and minimizes errors throughout the production process?

What methods can be developed to ensure that new team members and technicians properly understand and adopt the design of the system and its applications?